Hiatran Retrofits Stenter Hot Air Circulation System with Synchronous Reluctance Technology

Share

What is a Stenter Machine?

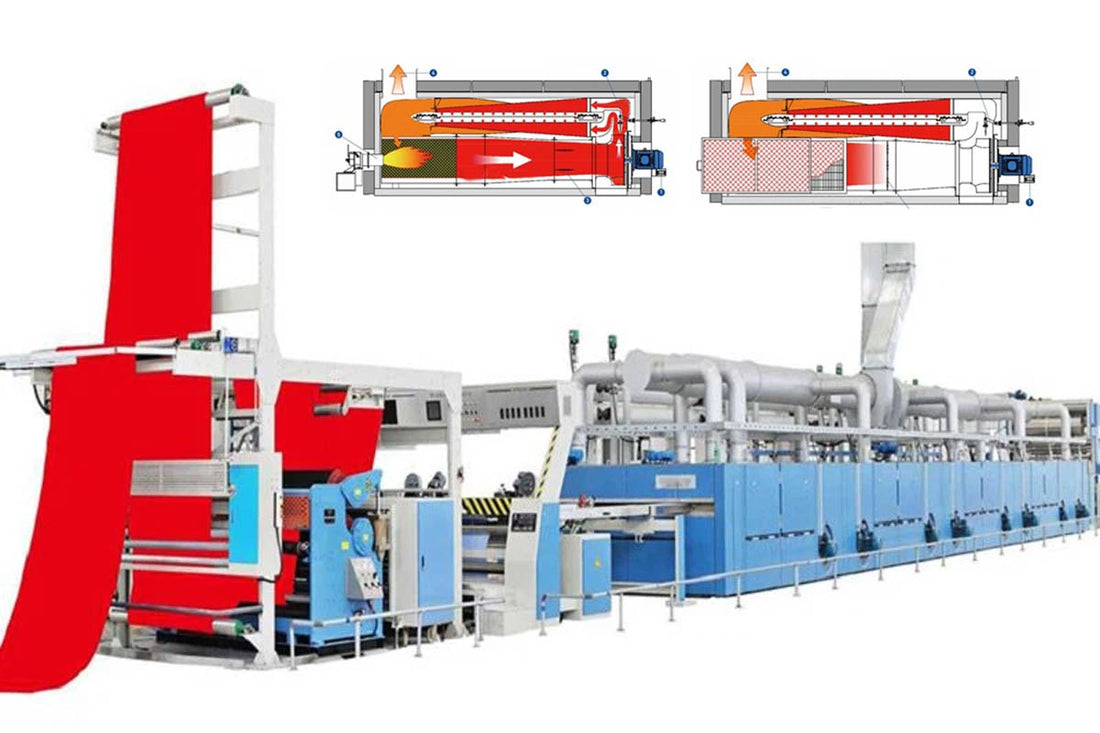

A stenter machine is a crucial post-finishing equipment in the textile printing and dyeing industry, characterized by large installed capacity, high energy consumption, and a significant number in operation. Most of the motors configured in current stenter machines are in the IE2 efficiency range, which has a narrow high-efficiency zone and consumes considerable energy. The stenter machine is a key piece of equipment in the dyeing and finishing process. By processing textiles at high temperatures, the stenter machine improves characteristics such as fabric width, weight, texture, and color, while also stabilizing the dimensions of the textiles.

The hot air circulation system of the stenter machine is used to heat the textiles. It generally comes in two main types: natural gas heating and steam/thermal oil heating. A single stenter machine typically contains about 18-20 hot air fans, with motor specifications generally around 7.5 kW and 1500 rpm. The circulation fans represent a large portion of the equipment’s capacity and are the primary consumers of electrical power.

Operating Conditions Overview

Load Characteristics:

The system operates under fan load with a quadratic torque profile. At low speeds, the load torque is low, and the output power is small. At high speeds, the load torque increases, and the output power rises accordingly. In high-temperature environments, the air density is lower, resulting in reduced load torque, whereas in normal temperatures, the higher air density leads to higher load torque. The system typically operates in high-temperature, low-load conditions for extended periods.

Operating Environment:

The environment features high temperatures and high humidity. The hot air fan transports heated air at temperatures ranging from approximately 140-220°C. The heat from the air is transferred through the impeller and motor shaft into the motor, further increasing the motor's internal temperature. As the air is heated, its density decreases, reducing the load torque on the fan in these thermal conditions.

Starting Characteristics:

The system requires reverse-wind starting capability. The internal air ducts are interconnected, and the fan's impeller may already be rotating due to the influence of other fans at the moment of motor start. Therefore, the motor must be capable of starting reliably even when the impeller is in a rotating state.

Power Configuration:

The common power configuration includes a three-phase asynchronous motor coupled with a variable frequency drive (VFD). However, the motor efficiency is relatively low, with a narrow high-efficiency zone. The system frequently operates in low-efficiency regions, resulting in poor overall energy efficiency and high operational costs.

Hiatran Electric Motor Solutions

This Retrofit Project Relies on Ultra-High-Efficiency Assisted Magnetic Synchronous Reluctance Motor Technology. The energy-saving retrofit targets the fan motor drive system of the stenter machine, utilizing HCM5G series ultra-high-efficiency assisted magnetic synchronous reluctance motors as the main drive motor. These motors offer advantages such as low energy consumption, a broad high-efficiency range, compact size, and cost-effectiveness. The G6 series drive is selected as the motor's drive control device, featuring vector control and a dedicated low-level algorithm for assisted magnetic motors, providing excellent control performance with high stability and efficiency.

HCM5G Assisted Magnetic Synchronous Reluctance Motor for Textile Printing and Dyeing Machinery

Motor Product Introduction

The HCM5G series is a high-temperature-resistant three-phase assisted magnetic synchronous reluctance motor, specifically developed for high-temperature applications such as textile printing and dyeing machinery. It is based on the HCM5 series of assisted magnetic synchronous reluctance motors. The motor meets the top-tier energy efficiency requirements of the national standard (IEC Standard: IE5), offering high efficiency and low noise and vibration levels. Since the motor does not contain rare-earth permanent magnets, it eliminates the risk of demagnetization at high temperatures. It is equipped with specialized high-temperature bearings capable of withstanding up to 250°C, and oil injection and discharge devices are installed on both end covers for easy maintenance.

- Voltage Level: AVC 380V

- Power Range: 5.5-15 kW

- Frame Size: 132-160

- Efficiency Rating: IEC60034-30-2 IE5 efficiency

- Speed Range: 750/1000/1500/3000 rpm

Motor Product Features

-

High Efficiency:

The rotor has no losses, resulting in high efficiency and a wide high-efficiency range, providing excellent operational cost-effectiveness. -

High Power Factor:

The motor uses ferrite magnetic materials for auxiliary excitation, which minimizes reactive power and enhances the power factor. -

High Reliability:

Designed to withstand high temperatures, humidity, and corrosive environments, the motor has a low risk of demagnetization, ensuring high reliability. -

High Economic Value:

The motor primarily relies on reluctance torque, does not use rare-earth permanent magnet materials, and avoids costly raw materials such as high-grade silicon steel sheets. The drive system employs a transmission frequency converter hardware architecture, making it a cost-effective IE5 energy-efficient motor drive solution with excellent economic benefits.

This combination of high efficiency, reliability, and cost-effectiveness makes the HCM5G series ideal for applications in demanding environments like those found in textile dyeing and finishing machinery.

Drive Product Introduction

The HCD-G6 series frequency drive is a high-performance, general-purpose current vector drive designed for speed and torque control of assisted magnetic synchronous reluctance motors. It uses advanced vector control technology, providing excellent dynamic control characteristics and overload capacity. The drive supports speed tracking for the entire speed range at startup, making it suitable for various automated production equipment. It features a wide range of input and output interfaces and supports expansion.

- Input Voltage: 3PH 380V ±10%, 50/60Hz

- Power Range: 0.75-500 kW

- Installation Type: Wall-mounted installation

Drive Product Features

- Supports open-loop/closed-loop vector control across the entire speed range for assisted magnetic synchronous reluctance motors.

- Offers excellent dynamic performance, starting capability, overload capacity, and constant power speed extension capability.

- Provides both speed and torque control modes.

- Built-in Modbus and CAN communication protocols.

- Capable of speed tracking during startup across the full speed range.

The HCD-G6 drive delivers robust control performance, making it ideal for use in various industrial applications that demand precision in motor speed and torque control.

Original Drive System:

- Motor: YE2-132M-4 Three-phase asynchronous motor

- Power Rating: 7.5 kW

- Speed: 1500 rpm

- Energy Efficiency: IE2

- Drive: Standard frequency inverter

New Drive System:

- Motor: HCM5G Assisted Magnetic Synchronous Reluctance Motor

- Drive: HCD-G6 Synchronous Reluctance Drive

- Energy Efficiency: IE5