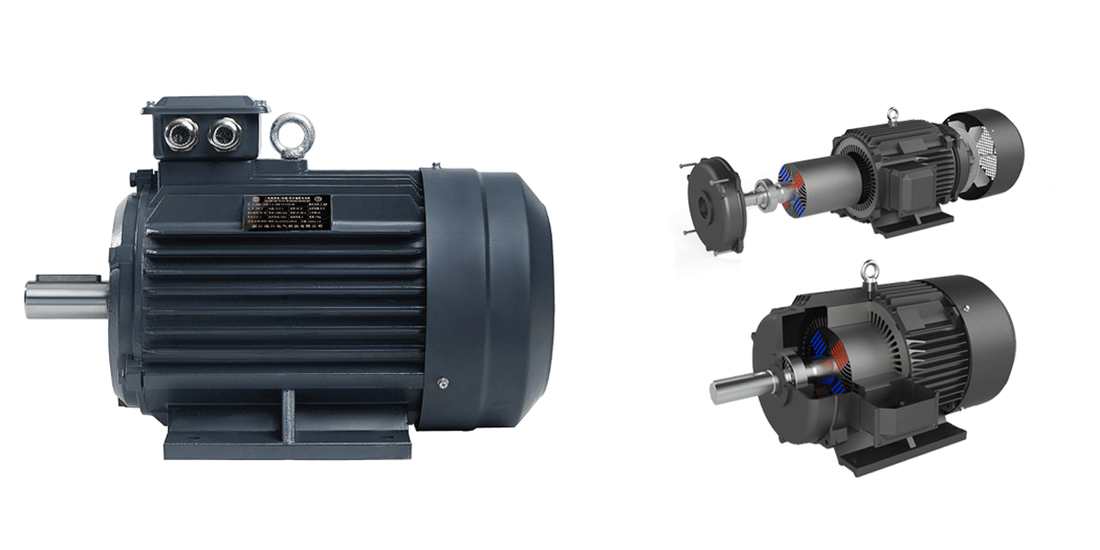

Hiatran IE5 Magnet-Assisted Synchronous Reluctance Motors

Share

Hiatran Electric is a Chinese company that is primarily engaged in the research, development, production and sale of industrial high-efficiency motors and drives. As China's manufacturing industry continues to develop, the number of motors continues to increase. In 2023, the total number of motors will be 3.25 billion kilowatts, accounting for 60% of the total electricity consumption and 25% of the total carbon emissions. High-efficiency motors account for less than 10%.

Hiatran Electric discovered the market potential of high-efficiency motors and developed and produced magnetic-assisted synchronous reluctance motors. It is a further upgrade on the basis of synchronous reluctance motors, with the IEC energy efficiency level increased from IE4 to IE5. With variable frequency drives, it is even estimated to reach IE6, 20% reduction in energy losses compared to similar IE5 motors.

What is Magnet-Assisted Synchronous Reluctance Motor?

SynRMs work on a very elegant principle that has been known for a long time, but only its high energy efficiency can only be realized when paired with a suitable variable-speed drive (VSD).

In a SynRM, the rotor is designed to produce the smallest possible magnetic reluctance (the resistance to the flow of a magnetic field) in one direction and the highest reluctance in the direction perpendicular. The VSD steers the stator field so it “rotates” around the motor. The directionally unequal magnetic reluctance properties of the rotor cause the rotor to rotate with the field and at the same frequency.

SynRM technology combines the performance of the permanent magnet motor with the simplicity and service-friendliness of the induction motor, as SynRMs do not feature rare-earth-based like permanent magnets. The rotor has neither magnets nor windings and suffers virtually no power losses. And because there are no magnetic forces in the rotor, maintenance is as straightforward as with induction motors.

The magnetically assisted synchronous reluctance motor is based on the SynRM motor, using ferrite as a magnet to further improve efficiency. Compared with the rare earth permanent magnet materials (such as NdFeB) commonly used in permanent magnet motors, the cost of ferrite is greatly reduced. In addition, ferrite materials have good temperature stability and are not easy to demagnetize. When working in a high temperature environment, the performance of ferrite is relatively stable, while the magnetism of rare earth permanent magnet materials may be significantly reduced at high temperatures. Therefore, ferrite-assisted synchronous reluctance motors have advantages in high temperature environments.

IE5 SynRM VS YE2 Asynchronous Motor

Comparison of actual Hiatran test data shows that the SynRM IE5 motor has advantages over the YE2 motor, including under partial load conditions, where the advantages are more obvious than at the nominal point.

The graph below shows the typical efficiency performance of an IE5 SynRM versus an YE2 motor in pump duty according to Hiatran laboratory measurements.IE5 has a wider high efficiency range and can achieve higher efficiency under different loads.

Higher Temperature Resistance And Compatibility

The internal magnets of the motor are made of ferrite permanent magnets, which are more temperature-resistant than rare earth permanent magnets and will not demagnetize at high temperatures. This is more advantageous in some high-temperature use scenarios.

The HCM5 external rotor uses the housing of a general three-phase induction motor with the same size. No mechanical modification is required when upgrading, so traditional induction motors can be easily replaced. This compatibility also simplifies spare parts supply and maintenance.

IEC TS 60034-30-2

The IEC 60034-30-1 technical standard for IE efficiency classification has now been superseded by IEC 60034-30-2:2016, which defines new efficiency classes of variable-speed AC motors that cover, for the first time, IE5 SynRMs.

The new standard allows direct comparison at the IE class level of traditional induction motors in variable-speed usage with advanced technology motors designed only for VSD (like SynRMs). In practice, IE5 motors have 20 percent lower losses compared to an IE4 motor, regardless of the technology or IEC standard used.

Energy Savings Payback

For motors of equivalent specifications, the initial cost price difference between an IE5 SynRM motor and a YE2 motor is negligible compared to the annual energy cost savings. Energy and cost savings for an IE5 motor set compared to a YE2 motor set are realized as soon as it is put into operation, with the cost difference paid back in approximately 12 months. The savings generated by reduced energy use over the remaining operating life (10-15 years) will pay back the initial cost of the entire IE5 motor set.