IE5 High-efficiency Motor Retrofit——Plastic Extrusion Machine

Share

Background

Extrusion molding is one of the main processing methods in plastic molding technology. At present, extrusion molding has been widely used in daily necessities, agriculture, construction, petroleum, chemical industry, machinery manufacturing, electronics and other sectors. Most of the motors configured for existing plastic extruders are IE3 and below energy efficiency, with a narrow overall economic operation range and high energy consumption. Under the trend of energy conservation, it is necessary to optimize more efficient and more suitable motors and drive solutions. Hiatran customizes more efficient IE5 energy-efficient motor plans for professional manufacturers to optimize and upgrade existing plastic extruders to make them more stable and cost-saving.

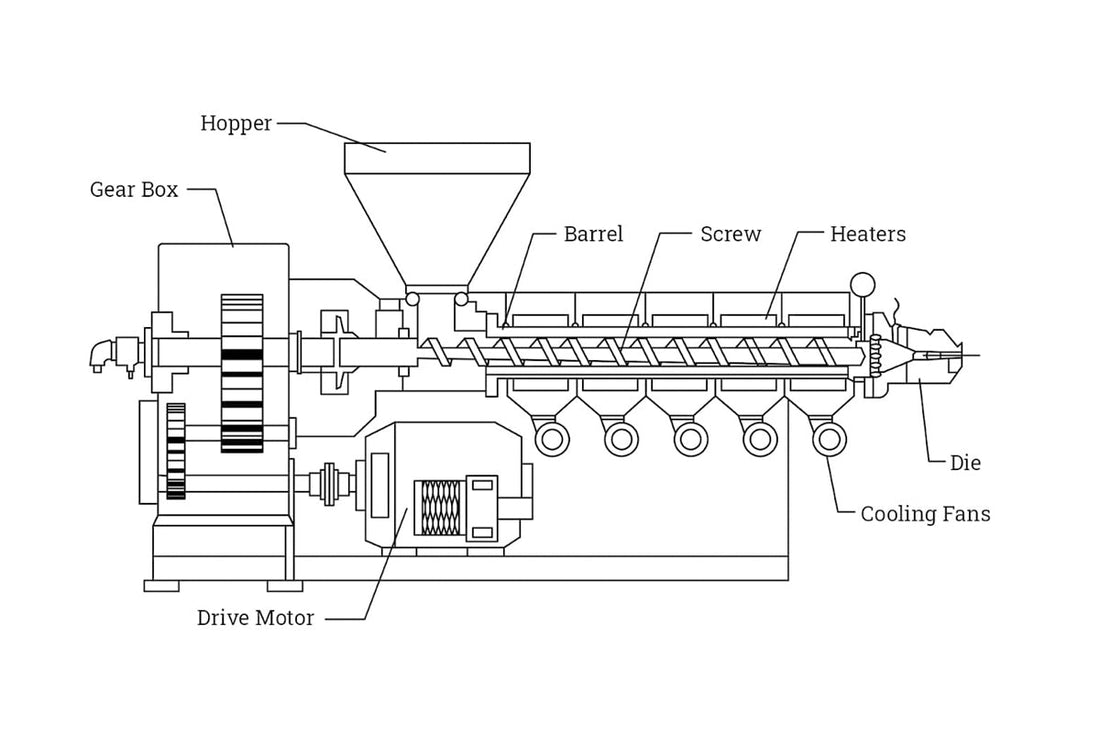

Equipment Introduction

The three major categories of plastic machinery are injection molding machines, extruders and blow molding machines, which account for more than 80% of the total output value of plastic machinery. Plastics are plasticized into a uniform melt through the extruder. Under the pressure established during plasticization, the motor drives the screw to continuously extruder the head with constant temperature, quantity and pressure. Plastic extruder (main machine) can be matched with various plastic molding auxiliary machines such as pipes, films, braids, monofilaments, flat wires, strapping tapes, extruded nets, plates (sheets), profiles, granulation, cable coating, etc. to form various plastic extrusion molding production lines and produce various plastic products.

Working Conditions

① Load characteristics:

Screw drive, constant torque load. The output power increases with the increase of speed. Due to different processing materials, some extrusion processes require a relatively low speed, while some extrusion processes require a relatively high speed. Therefore, the transmission of the extruder must have the same torque output between low speed and rated speed to achieve a high efficiency ratio.

② Operating environment:

The motor runs near the thermoplastic machine, and the temperature will be slightly higher than the environment. Because it is a constant torque load, some processes require a low speed, so the motor is best equipped with forced air cooling, otherwise it will affect the heat dissipation of the motor.

③ Starting characteristics:

The starting torque is large, and the speed fluctuation is relatively small when the sudden load is added or released.

④ Power configuration:

The commonly used power configuration is a three-phase asynchronous motor + inverter solution. The motor has low energy efficiency, a narrow high-efficiency range, often runs in a low-efficiency area, and has poor comprehensive electricity economy.

Haichuan Electric Solution

This transformation relies on ultra-high-efficiency magnetic-assisted synchronous reluctance motor technology, and takes the mill motor drive system as the energy-saving transformation object. The HCM5 series ultra-high-efficiency magnetic-assisted synchronous reluctance motor is used as the main drive motor, which has the characteristics of low energy consumption, wide high-efficiency range, small size, reliable and economical. The G6 series driver is selected as the motor drive control device, vector control, and the underlying algorithm dedicated to the magnetic-assisted motor, with good control performance, stable and efficient.

After replacing the motor drive solution, the specific data measured are as follows.