What is a Synchronous Motor?

Share

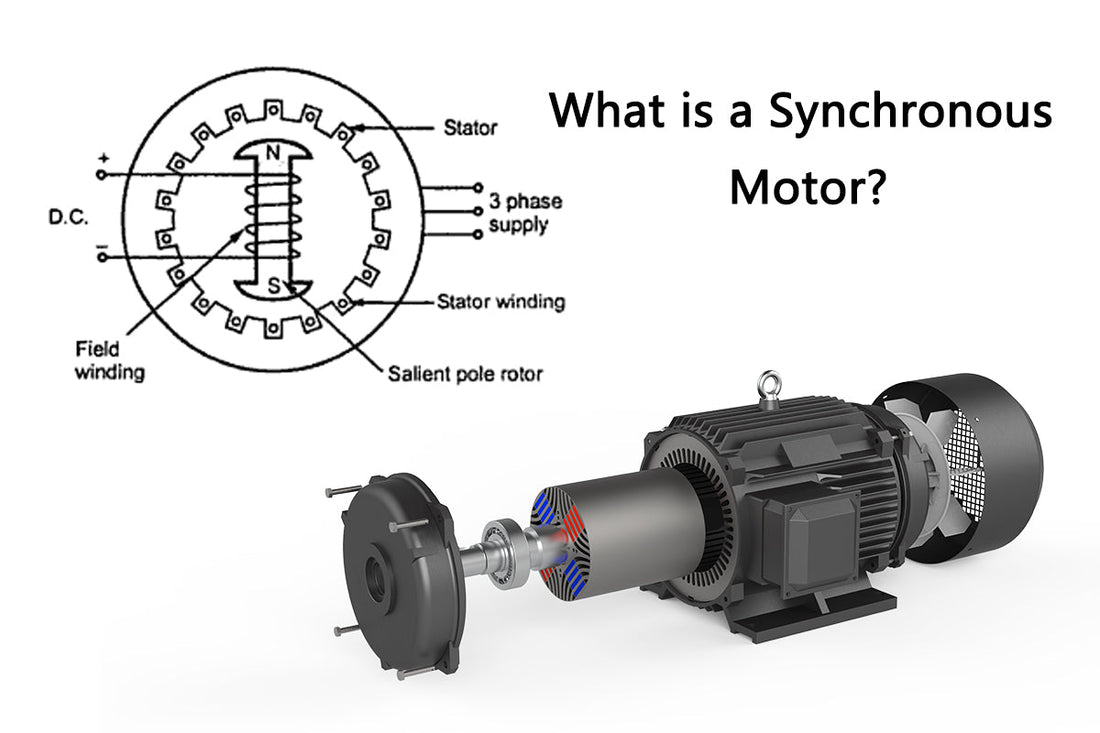

A synchronous motor is an electric motor that operates at a constant speed, directly proportional to the frequency of the power supply. Unlike induction motors, which operate at a speed slightly lower than the synchronous speed, a synchronous motor’s rotor speed is always synchronized with the rotating magnetic field generated by the stator. This unique feature makes synchronous motors ideal for applications where precise speed control is required, such as in power generation, industrial pumps, fans, and precision machinery.

Working Principle of a Synchronous Motor

The operating principle of a synchronous motor is based on electromagnetic induction. The stator, which is supplied with alternating current (AC), generates a rotating magnetic field. This magnetic field interacts with the rotor, which typically contains either permanent magnets or an electromagnet powered by an excitation system.

In operation, the rotor locks into the rotating magnetic field of the stator, resulting in the rotor spinning at a speed that is exactly in sync with the stator's field. The speed at which the motor operates (synchronous speed) depends on the frequency of the AC supply. This synchronization ensures that the motor maintains a constant speed regardless of the load, making it ideal for applications requiring steady and reliable performance.

Types of Synchronous Motors

- Permanent Magnet Synchronous Motor (PMSM): The rotor of a permanent magnet synchronous motor is equipped with permanent magnets, eliminating the need for external excitation. PMSMs are highly efficient, low-maintenance, and commonly used in high-efficiency drive systems.

- Wound Rotor Synchronous Motor: In this type of motor, the rotor has a winding that requires an external excitation current. Wound rotor synchronous motors are typically used in high-power applications and are capable of providing high starting torque.

Advantages of Synchronous Motors

- Stable Speed: Synchronous motors maintain a constant speed, which is crucial in applications like generators and precision machinery, where speed control is critical.

- High Efficiency: Synchronous motors are more efficient than induction motors, especially under heavy load conditions. Because there is no slip between the rotor and the stator magnetic field, energy losses are minimized.

- No Slip: Unlike induction motors, which experience "slip" (a slight difference between the rotor speed and synchronous speed), synchronous motors operate at the exact synchronous speed, ensuring consistent and reliable performance.

- Power Factor Control: By adjusting the excitation current, synchronous motors can be used to regulate the power factor in a power system, improving the overall efficiency of the electrical grid.

Disadvantages of Synchronous Motors

- Difficult to Start: Starting a synchronous motor is more complex compared to an induction motor. The rotor must be brought up to synchronous speed by external means, such as using a variable frequency drive (VFD) or a starting excitation current.

- Higher Maintenance Requirements: Wound rotor synchronous motors, in particular, require more maintenance due to their excitation system and components like brushes and slip rings.

- Higher Cost: Synchronous motors are generally more expensive to manufacture and maintain than induction motors, particularly permanent magnet synchronous motors, which use rare-earth materials.

Applications of Synchronous Motors

- Generators: Synchronous motors are often used as generators in power plants. These motors must maintain a precise speed to ensure the generated electricity matches the frequency of the grid.

- Industrial Drives: Synchronous motors are employed in industrial applications requiring constant speed, such as precision machine tools, textile machinery, and conveyor systems.

- Power Factor Correction: Synchronous motors can be used in power systems to provide reactive power compensation, helping to improve the overall power factor and efficiency of the grid.

- High-Efficiency Drive Systems: Permanent magnet synchronous motors (PMSMs) are increasingly used in electric vehicles, wind turbines, and other high-efficiency drive applications due to their low maintenance requirements and high performance.

Conclusion

Synchronous motors play a vital role in industrial and energy sectors, particularly in applications where precise speed control and high efficiency are critical. Although they pose challenges in terms of startup and maintenance, the advent of technologies like permanent magnet synchronous motors has made them more accessible and cost-effective. As the demand for energy efficiency and precise control continues to grow, synchronous motors are expected to become even more prevalent in various industries, offering an ideal solution for power generation, industrial automation, and high-performance systems.